The three pillars of smarter pipeline maintenance

You’ve got a job to do. And that job doesn’t include wasting time chasing false positives or second-guessing your leak detection system. PipeSense rewrites the playbook with a powerhouse trio of technologies designed to work smarter, not harder. These three core systems don’t just operate side by side—they work in sync, amplifying accuracy, cutting through noise and providing critical data with unprecedented speed and precision.

Pressure

Think of it as sonar for your pipeline, sharper and ridiculously accurate. This technology fuels every PipeSense solution—whether it’s detecting leaks in real time, pinpointing pre-existing leaks, tracking stuck pigs or ensuring hydrotests run with next-level precision.

Others have tried pressure-based diagnostics, but they lacked the ultra-high-speed sampling, data precision and signal processing expertise to get it right. We built a system that not only works—it delivers immediate, high-confidence results that cut out the inefficiencies that have plagued the industry for decades.

- Leak Detection: Immediately differentiates false positives from real leak events

Explore Permanent Leak Detection - Hydrotesting: Real-time “true” pressure tests

Explore Hydrotesting - Obstruction locator: Identifies blockages with unparalleled accuracy

Explore Obstruction Locator - Pre-Existing Leak Detection: Finds leaks that others miss before they become bigger problems

Explore Pre-Existing Leak Detection

Advanced Data Analysis

Pipelines speak in frequencies — subtle pressure changes and abrupt pressure swings that tell the real story. PipeSense deciphers that story in full detail. From our 3D frequency plots and advanced filtering and pattern matching, capture and analyze pipeline signals, revealing insights that others miss.

- Leak Detection: Provides another layer of defense against false positives to cut through the noise and deliver only insights that matter

Explore Permanent Leak Detection - Hydrotesting: Enhances pressure analysis for faster stabilization and fail-proof testing

Explore Hydrotesting - Obstruction locator: Distinguishes complex pressure reflections from background noise to allow for super-accurate location

Explore Obstruction Locator - Pre-Existing Leak Detection: Validates the presence of

pre-existing leaks for total pipeline health transparency

Explore Pre-Existing Leak Detection

AI/ML

Machine learning at PipeSense doesn’t run on blind automation — it runs on expertise. Every test, every pressure shift and every anomaly feeds into a continuously evolving model that sharpens with every trial. With over 35,000 hand-curated pressure events and counting, our system is constantly improving—but never at the expense of operator control.

Our models are rigorously trained in-house by the industry’s sharpest minds to ensure rapid learning that recognizes patterns, eliminates inefficiencies and transforms raw data into instant, inspired action.

- Leak Detection: AI-powered event recognition instantly verifies leaks and prevents false alarms

Explore Permanent Leak Detection - Hydrotesting: Separates pump and valve noise from leak signatures, providing pinpoint accuracy.

Explore Hydrotesting - Obstruction locator: Clear identification of reflective signatures enhances location accuracy.

Explore Obstruction Locator - Pre-Existing Leak Detection: AI-driven diagnostics identify hidden leaks that traditional methods miss.

Explore Pre-Existing Leak Detection

Can’t stop, won’t stop innovating

Our team thrives in a constant state of problem solving. We live at the whiteboard, trying to find better, faster and more accurate ways forward.

Inspired by the field, not the boardroom

Our best ideas don’t come from sitting in a conference room. They come from working alongside operators, listening to the frustrations of real-world pipeline challenges and designing solutions that work under pressure. We saw an industry bogged down by inefficiencies, false positives and technology that required constant (and costly) hand-holding. Every breakthrough we’ve made comes from asking the right questions, challenging the status quo and never settling for “good enough.” There’s nothing more common sense than that.

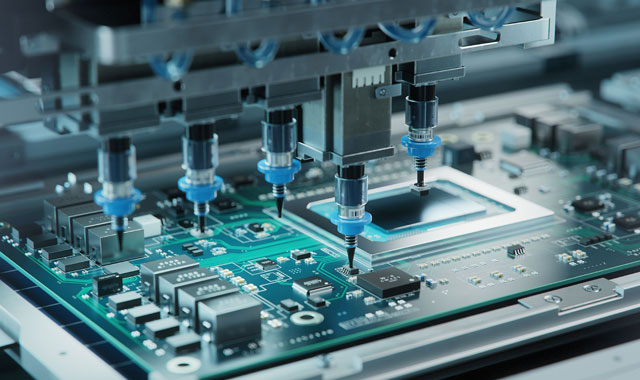

From whiteboard to real-world

Our commitment to hands-on development means we don’t just build new technology—we test, break, and refine it until it delivers seamless, high-confidence results in the field. At our test loops in Katy, TX and Clearbrook, MN, we push each detection method, data model and hardware component to its limit, making sure “it just works” at the highest level.

Our people make it all possible

Behind every breakthrough at PipeSense is a team that thrives on solving the toughest pipeline challenges. Engineers, project managers, support staff — each brings deep expertise, relentless curiosity and a drive to make things work better.